Figure 1: Implementing five linguistic principles in technical communication prevents costly errors in automated 5-axis machining by eliminating ambiguity between design intent and physical execution.

Introduction

In high-end manufacturing, a rarely discussed bottleneck is silently eroding profits: communication ambiguity. When a design engineer’s intent for a “sharp edge break” is interpreted as 0.1mm by a manufacturing engineer but executed as 0.25mm by a machine operator, the result for expensive components undergoing 24/7 automated 5-axis machining can be batch failures in fit or aerodynamic performance. Research indicates that over 50% of project rework can be traced back to ambiguities in requirement documents and technical drawings.

The root cause is the lack of a standardized “linguistic protocol” that connects design intent with physical manufacturing. This gap causes deviations in how automated systems interpret complex instructions, jeopardizing the reliability of unattended production.

This article argues that the systematic application of linguistic precision principles to technical communication is key to unlocking the full potential of automated 5-axis machining. We present a framework of five principles, derived from linguistic logic and validated by precision manufacturing practice, capable of reducing communication-induced scrap rates by up to 70%.

Why Does Semantic Ambiguity in Technical Drawings Directly Translate to Physical Machining Errors?

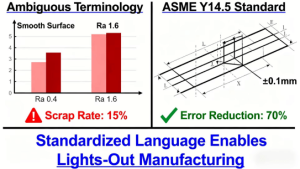

The subjectivity of terms like “smooth surface” or “tight fit” is a hidden cost driver in precision manufacturing. A real-world case saw an aerospace component cause significant scratch damage during assembly due to differing interpretations of “burr-free,” resulting in massive financial loss. This semantic ambiguity is amplified in automated environments, where CNC systems follow programming instructions literally, without human judgment.

- The Gold Standard for Unambiguous Communication: The solution lies in adopting a universal engineering language. The ASME Y14.5Dimensioning and Tolerancing standard serves as this gold standard. Like grammatical rules, it provides an unambiguous “vocabulary” and “syntax” for dimensions and tolerances, ensuring any trained engineer interprets a drawing identically.

Figure 2: The ASME Y14.5 dimensioning and tolerancing standard provides unambiguous communication rules, reducing interpretation errors by up to 70% in automated 5-axis machining environments.

- The Direct Link to Automated Reliability: In automated CNC machining, clear semantics are the foundation for systems performing automatic fixturing and quality checks. Ambiguous instructions cause these systems to fail or produce inconsistent results, forcing manual intervention and defeating the purpose of lights-out manufacturing. Adopting standards like ASME Y14.5 is fundamental to building a reliable data flow for automated 5-axis machining.

How Can Structured Technical Writing for Automated Systems Minimize Human Intervention?

True automation depends on seamless information flow, not just hardware. A poor process plan may use vague verbs like “handle“, while an excellent one employs consistent terms (e.g., “mill”), explicit sequences, and “if-then” logic.

1.The Concept of a “Manufacturing Playbook”

The solution is creating a “Manufacturing Playbook.” This involves writing every operational step, parameter, and inspection point in a standardized, machine-parsable format. This not only reduces operator cognitive load and training time but is a prerequisite for unattended operation.

2. The Power of Consistent Syntax

Much like programming languages rely on strict syntax, a manufacturing playbook uses uniform sentence structure to translate complex machining intent into repeatable, verifiable instructions. This structured technical writing approach minimizes the interpretive gap between human intent and machine action, directly enhancing the efficiency and reliability of CNC machine tending.

What is the Role of Analogies and Metaphors in Bridging the Knowledge Gap Between Design and Manufacturing?

In cross-disciplinary teams, complex concepts like 5-axis tool-path tracking can be challenging for non-mechanical members (e.g., project managers). Here, the artistry of language – specifically analogies and metaphors – becomes critical.

- Making the Complex Tangible: For instance, comparing 5-axis simultaneous machining to “the tool tip dancing perpendicular to the surface” creates an instant visual. Analogies like “stacking building blocks” explain tolerance stack-up, while the distinction between a “scalpel and a cleaver” differentiates finishing from roughing strategies. These industrial metaphorsbuild intuitive understanding.

- Accelerating Project Consensus and Alignment: This communication method significantly speeds up project reviews and ensures all stakeholders align on technical challenges and solutions. It fosters deep cross-disciplinary understanding, translating abstract jargon into a shared mental model, thereby reducing future change orders caused by misinterpretation.

How Does a Standardized Communication Protocol Underpin True Lights-Out Manufacturing Reliability?

The reliability of lights-out manufacturing hinges on the robustness of every communication link. One weak point – like an unclear material changeover instruction – can halt the entire automated production line.

1. Beyond Hardware: The Information Flow Automation

This requires elevating communication best practices from individual experience to organizational policy. Clauses on “organizational knowledge” and “documented information” within the ISO 9001:2015 Quality management systems standard provide the framework for this standardization. Documenting communication protocols is an integral part of a quality management system.

2. Building Institutional Knowledge

By standardizing terminology, playbooks, and reporting formats, companies can embed critical knowledge into organizational processes. This ensures consistent output across different shifts and roles, building the trust required for lights-out manufacturing. A quality management system adhering to standards like ISO 9001 is the bedrock of this reliability.

Can Storytelling Techniques Effectively Communicate the ROI of Complex Automation Investments?

Justifying an investment in an automated 5-axis cell to decision-makers requires more than listing technical specs. Using a narrative approach to build the business case is far more effective.

H3: 1. Crafting the Investment Narrative

An effective story framework includes:

- The Challenge:Describe the current pain points (e.g., unused night-shift capacity, high scrap rates from communication errors).

- The Journey:Explain the implementation process, highlighting how linguistic principles solve communication bottlenecks.

- The Resolution:Showcase results with concrete data, e.g., “reduced piece-cycle time from 5.2 hours to 2.1 hours, achieving 95% equipment utilization and 8% qualification rate.”

2. Data-Driven Storytelling

Embedding specific, credible data into the narrative is crucial. This simplified explanation of complex concepts is more persuasive than generic claims of “improved efficiency”, helping technical teams secure executive support and funding for technological upgrades.

Conclusion

In precision manufacturing, linguistic ambiguity is an unaffordable luxury. By systematically applying these five principles of linguistic precision, manufacturing enterprises can transform communication from an “art” into a managed engineering discipline. This not only builds the foundation of trust required for automated 5-axis machining — ensuring digital instructions in 5-axis-CNC-machining processes are accurately converted into high-quality physical parts — but also creates a powerful, hard-to-replicate competitive advantage: seamless and highly efficient internal and external collaboration.

H2: FAQs

Q1: How quickly can we expect to see a reduction in errors after implementing these principles?

A: Organizations typically observe a measurable reduction in documentation-related errors within the first 3 months. The most significant improvements (up to 70% reduction) are often realized after 6-12 months, as the standardized terminology becomes ingrained in the company culture.

Q2: Are these principles relevant for small-scale workshops, or only for large corporations?

A: The principles are universally applicable and scalable. Small workshops can often implement them more rapidly due to less bureaucracy. Clear communication prevents costly one-off errors that are more devastating for smaller businesses, making these principles a powerful tool for safeguarding profitability.

Q3: We already use PLM/MES systems. How does this framework integrate with them?

A: This framework enhances the value of your PLM/MES investments. These systems are databases; the linguistic principles govern the quality and clarity of the information entered. Clear input leads to reliable automated output, preventing “garbage in, garbage out” and ensuring your digital thread is strong and unambiguous.

Q4: What’s the biggest hurdle in implementation, and how can it be overcome?

A: The biggest challenge is often cultural resistance to changing established communication habits. The most effective way is to start with a pilot project focused on a high-impact, recurring error. Demonstrating a quick win (e.g., eliminating a specific defect) through terminology alignment builds momentum and buy-in.

Q5: Can these ideas help in communicating with international suppliers who have language barriers?

A: Absolutely. Standardized terminology and visual aids (like well-defined GD&T symbols on drawings) create a universal language that transcends spoken language. Reducing reliance on verbose, idiomatic text in favor of precise symbols and standardized terms significantly reduces misinterpretation in global supply chains.

H3: Author Bio

The insights presented in this article derive from the extensive hands-on experience of LS Manufacturing in serving global high-end manufacturing clients. As a certified one-stop solutions provider, the company specializes in guiding clients toward manufacturing excellence from prototype to production, backed by a quality system certified to ISO 9001, IATF 16949, and AS9100D.

For deeper implementation guidance, consider these pathways:

- Discuss Tailored Solutions: Schedule a consultation to address your operation’s specific challenges and opportunities.

- Explore Technical Resources:Inquire about additional resources for design and manufacturing optimization.