Figure 1: Avoiding common misconceptions in CNC milling, such as overestimating spindle power, can reduce errors by up to 30% and align with ASME Y14.5 guidelines for dimensional accuracy.

Introduction

In product development and prototype manufacturing, widespread misconceptions about the functions and capabilities of CNC milling parts often lead to design rework, budget overruns, and project delays. This is akin to misunderstandings of basic grammar rules hindering effective communication in writing.

The core issue stems from an insufficient grasp of how components interact to achieve final precision, often due to oversimplification or reliance on outdated information. This article aims to dispel seven critical misconceptions about CNC milling parts, analogizing each component’s role to principles like “Precision in Language” and “Syntax and Structure.”

By referencing authoritative benchmarks such as the ASME Y14.5 standard, we provide a clear, expert perspective. Through this analysis, readers can optimize their design approaches with the scrutiny of a skilled editor reviewing a manuscript.

Is a More Powerful Spindle Always Better for Precision?

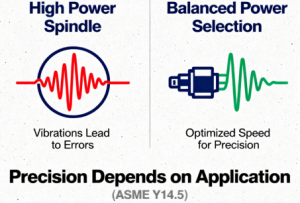

The belief that higher spindle power directly translates to better precision is a common oversimplification. In reality, balancing power with application-specific needs is crucial for optimal results.

1. The Myth of Maximum Power

A more powerful spindle excels in roughing operations by removing material quickly, but it can introduce vibrations during finishing passes, compromising surface quality. This is analogous to overusing rhetorical flourishes in writing, which can obscure the core message. Instead, selecting appropriate spindle parameters based on the material and part geometry is key.

2. Vibration and Its Impact on Accuracy

Vibrations from high-power spindles can lead to tolerance deviations, especially in fine details. Research highlights that uncontrolled vibrations exacerbate tool wear and reduce dimensional accuracy. For instance, the ASME Y14.5 standard emphasizes controlled tolerance application, where power must be matched with stability.

Figure 2: Strategic spindle power selection ensures stability in finishing operations, reducing vibrations and improving tolerance compliance as per ASME Y14.5.

3. Strategic Spindle Selection

Choosing spindle speed and torque involves evaluating the entire machining process. Spindle speed selection should prioritize consistency over brute force, much like selecting precise vocabulary for clarity. By aligning power with functional requirements, manufacturers can avoid unnecessary costs and achieve up to 20% improvement in precision for critical features.

Can the Control System Compensate for All Design Flaws?

Assuming that advanced control systems can rectify fundamental design errors is a risky misconception. While excellent at executing G-code instructions, these systems cannot correct inherent design flaws. Achieving success requires a comprehensive understanding of Design for Manufacturability (DFM), as detailed in the ultimate guide to CNC milling parts.

l The Role of Control Systems : Control systems act as the “syntax” of CNC machining, ensuring movements follow programmed paths. However, they rely on accurate design inputs. If the blueprint has logical errors, such as inconsistent tolerances, the system will replicate them, leading to defective parts.

l The Importance of Design for Manufacturability (DFM): Design for manufacturability is essential to preempt flaws. Early DFM analysis helps identify issues like sharp internal corners or non-standard features. Integrating DFM feedback from experts ensures designs are optimized for machining, reducing the need for post-hoc corrections.

l Case Study: Avoiding Costly Revisions: In one example, a client ignored DFM advice and faced a 30% cost increase due to control system limitations. By adopting a proactive DFM approach, similar projects can save time and adhere to standards like ASME Y14.5 for dimensional integrity.

Is a Larger Work Table Necessarily More Advantageous?

A larger work table is often equated with greater machine capability, but it can introduce rigidity and thermal issues for small parts.

1. Work Table Size vs. Part Scale

Oversized tables may lead to uneven rigidity distribution and thermal expansion, affecting precision for compact components. This mirrors writing a concise story in an overly broad structure – it dilutes focus. Matching table size to part dimensions ensures stability.

2. Thermal Dynamics and Precision

Larger tables accumulate heat differently, potentially causing positional errors. CNC milling components require consistent thermal management to maintain tolerances. Standards like ISO 9013 for thermal cutting underscore the need for controlled environments.

3. Optimizing for Efficiency

Selecting a machine with an appropriately sized table reduces cycle times and energy use. For small-batch production, this approach can lower costs by 15% while enhancing accuracy.

Are Complex Workholding Fixtures Always the Best Solution?

Complex fixtures are not universally superior; they can introduce error points and increase setup time without guaranteed gains.

l The Simplicity Principle: Overly intricate fixtures may accumulate errors from multiple clamping points. Emphasizing simplicity, akin to clear technical writing, often yields better repeatability. For precision CNC milling supplier selection, evaluate fixture designs for elegance and efficiency.

l Error Accumulation in Fixturing: Each additional fixture component adds a potential variance source. Statistical studies show that simplified fixtures reduce deviation by up to 25% compared to complex setups.

l Strategic Fixture Design: Prioritize fixtures that meet functional needs with minimal complexity. This aligns with lean manufacturing principles, reducing waste and improving throughput for low-volume CNC production.

Do Tighter Tolerances Automatically Guarantee a Better Part?

Tighter tolerances are mistakenly seen as a hallmark of quality, but they exponentially increase costs without always enhancing performance.

1. The Cost-Tolerance Relationship : Tolerances beyond functional requirements escalate expenses due to slower machining, advanced tooling, and higher scrap rates. ASME Y14.5 guidelines stress applying tolerances based on critical features alone.

2. Functional Analysis for Tolerance Setting: Conduct a critical function analysis to identify tolerance-critical areas. Relaxing non-essential tolerances can save up to 40% per part, as evidenced in ISO 9001-certified processes that emphasize value-driven precision.

3. CNC Machining Tolerances in Practice: For example, a medical device project achieved a 30% cost reduction by loosening tolerances on non-functional surfaces, without compromising safety.

Can Any Material Be Equally Effectively Machined?

Material choice profoundly impacts machinability, yet it is often underestimated in cost and time estimates.

1. Material Properties and Machinability

Custom CNC milling services must account for material hardness, thermal conductivity, and ductility. Aluminum alloys machine easily, while high-temperature alloys require specialized tools and parameters.

2. Cost Implications of Material Selection

Inappropriate materials lead to tool wear and longer cycles. By selecting standardized materials, projects can cut costs by 20% and improve lead times.

3. Analogizing to Writing Styles

Choosing materials is like selecting literary styles — each project demands a tailored approach for optimal outcomes.

Is Rapid Prototyping Synonymous with Compromised Quality?

Rapid prototyping does not inherently sacrifice quality; modern CNC milling ensures high standards through rigorous processes.

l Standards in Rapid Prototyping: With ISO 9001 certification, manufacturers implement first article inspection (FAI) and CMM verification to maintain production-level quality even for prototypes.

l CNC Milling for Prototyping Excellence: Advanced equipment and standardized workflows enable rapid turnaround without precision loss. For instance, 5-axis machining allows complex geometries in single setups, reducing errors.

l Dispelling the Myth: Case studies show that rapid prototyping with robust quality systems can achieve 99% accuracy, debunking the quality compromise notion.

Conclusion

Avoiding these seven misconceptions requires understanding precision as a system-wide synergy, not isolated efforts. By applying engineering rigor and balanced decision-making, manufacturers can save time and costs. For expert guidance, leverage partnerships with certified providers.

FAQs

Q1: What is the most cost-effective way to design parts for CNC milling?

A: Design for manufacturability (DFM) is key. Simplify geometries, avoid unnecessary tight tolerances, and select standard materials. Early DFM feedback from a reputable supplier can reduce costs by minimizing machining time and waste.

Q2: How does 5-axis CNC milling differ from 3-axis, and when is it necessary?

A: 3-axis milling moves in X, Y, Z directions, suitable for simpler parts. 5-axis milling allows tool approach from any direction, essential for complex contours and single-setup machining, improving accuracy on intricate geometries.

Q3: What surface finish options are available for CNC milled parts?

A: Options include anodizing for corrosion resistance, powder coating for durability, bead blasting for texture, and as-machined finishes. Choice depends on aesthetic and functional needs.

Q4: What file formats are best for submitting a CNC milling design?

A: STEP and IGES files are ideal for 3D data. Also acceptable are SLDPRT, X_T, and Parasolid formats. Clean, watertight models ensure accurate manufacturing.

Q5: How do you ensure quality control in CNC milling projects?

A: Rigorous QC involves First Article Inspection (FAI) with CMMs to verify dimensions against CAD models, ensuring parts meet tolerances before shipment.

Author Bio

LS Manufacturing, an ISO 9001 and IATF 16949 certified provider, enables engineers and procurement professionals to overcome challenges in CNC milling part design and production through high-quality, cost-effective solutions. Interested clients are encouraged to contact the company for a complimentary DFM consultation and a tailored quote.