Producing plastic parts using injection molding requires accuracy and efficiency, making it one of the most important manufacturing processes. In recent decades, China Injection Mold has become one of the world’s leaders in the production of injection molds, with many international businesses investing due to low prices, quick production, and an increasing standard of quality. This article examines the molds used in the China Injection Mold industry concerning their quality, cost, and production speed.

Quality Of Chinese Injection Mold

The quality of an injection mold from China is one of the determining factors that define how efficiently the molded parts perform, how long they last, and how reliable they are. For many years, manufacturers From China Injection Mold struggled with delivering consistent quality in their molds. In recent years, this has changed greatly. Many manufacturers of China Injection Mold accept global quality standards like ISO 9001 and TS 16949, which means they have quality control systems in place. China Injection Mold and many of its manufacturers are already meeting stakeholders’ expectations.

Material Selection – In order to fabricate High-quality molds, materials that can withstand wear and tear are required: Hardened steel H13, S136, P20, and Aluminum. Nowadays, a good number of Chinese Injection Mold manufacturers are using high grade materials obtained from different countries to improve the precision and longevity of the molds.

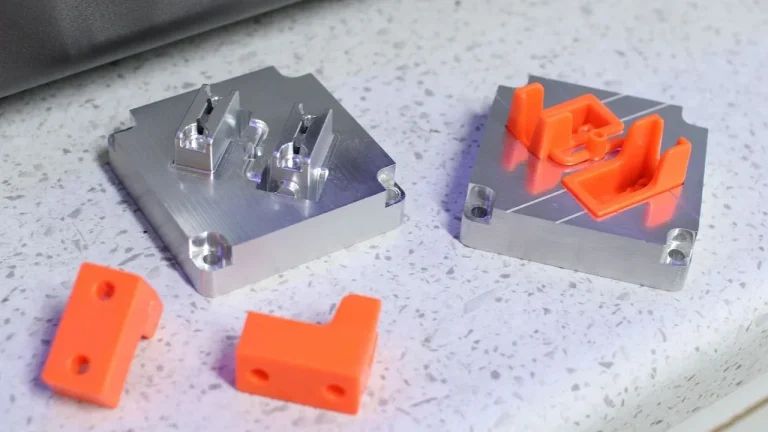

Advanced Manufacturing Techniques – Top-tier manufacturers employ CNC machining, EDM (Electrical Discharge Machining) and ultra-precise grinding for achieving fine tolerances as well as complex mold designs for fabrication.

Quality Control Processes – To comply with international requirements, Injection Mold factories in China put a lot of money into trying to meet required quality standards, which include CMM (Coordinate Measuring Machine) inspection, mold flow analysis, and extreme prototype testing prior to going into mass production.

Compared with Western Molds – Injection mold manufacturers in China have greatly improved their competitiveness, although western manufacturers like Germany or the USA still lead in ultra-high precision molds, China Injection Mold manufacturers offer comparable quality for much cheaper prices.

Although these improvements have been made, some low-cost suppliers still deliver sub-par quality products, which highlights the importance of thorough vetting and selection of suppliers.

Cost Difference: China Injection Mold and Other Countries

One of the most notable advantages of China Injection Mold is cost. The price range of China Injection Mold is based on a few factors, including:

Lower Labor Costs – People argue that wholesale wages in China have escalated, but it is still much less compared to the US, Europe, and Japan.

Efficient Supply Chain– China Injection Mold has a huge network of material suppliers, machine builders, and logistics centers, which leads to a decrease in general production expenses.

Large-scale Injection Mold -Manufacturing in China adopts cost-saving measures through automation and mass production of goods.

Support and Development Aid – The Chinese government subsidizes, and taxes support the development of Chinese Injection Mold industries, including investing in their infrastructure.

To show the difference in costs:

- An ultra-high precision injection mold from the USA costs about $15,000 to $50,000.

- A German counterpart can expect to pay between $20,000 and $70,000.

- With China Injection Mold, the same mold averages between $5,000 to $25,000, depending on the material quality and complexity of the mold.

While these prices can be great, ultra-cheap customers can result in poor quality service and increased maintenance expenses over time.

Production Speed: What is the China Injection Mold Manufacturer’s Speed Capacity?

This is another big benefit of China Injection Mold manufacturers. Compared to the West, China’s Injection Mold firms usually deliver projects on a quicker basis, owing to the following:

- China Injection Mold manufacturers maintain faster deliveries owing to having a high production capacity. A lot of these manufacturers are situated in industrial regions where they have many production lines and operate on a 24/7 basis.

- With the integration of automation and high-speed CNC machines, mold fabrication is done with the fastest turnaround times.

- The experience gained over the years in dealing with international orders has greatly helped China Injection Mold manufacturers optimize design-to-production workflows and reduce lead time.

- A number of China injection mold manufacturers provide fast prototyping services, including 3D printing and soft tooling. This allows for easy validation of the molds before proceeding to full-scale production.

Weaknesses Of China Injection Mold

China Injection Mold has various benefits in terms of cost and speed but there are still some challenges that must be addressed:

Intellectual Property (IP) Risks – Outsourcing to some China Injection Mold manufacturers may increase the likelihood of counterfeit and IP theft. To reduce risk, clients should work with certified companies while also signing Non-Disclosure Agreements (NDAs).

Communication Obstacles – Differences in language and culture may lead to miscommunication that affect intended specifications and expectations.

Shipping and Tariffs – Although manufacturing costs are low, other expenses like international shipping, import duties, and tariffs add to the total cost.

What To Consider When Choosing a China Injection Mold Manufacturer

In order to ensure quality, cost-effectiveness, and timely production, businesses need to follow some steps when choosing a China Injection Mold supplier:

Check Certifications – Ensure that the manufacturers have ISO 9001, IATF 16949, or other relevant quality certifications.

Review Experience and Portfolio – Established China Injection Mold manufacturers are more reliable if they have profound experience in specific sectors-automotive, medical, electronics, etc.

Request Samples and Audit – The first step is to order sample molds, or alternatively, you can go directly to the factory and conduct an audit (either in person or virtual).

Negotiate Contracts with Caution – Agreements should include the product descriptions, delivery schedules, payments, and method of assuring quality.

Employ a Local Sourcing Agent – Using a China Injection Mold-based sourcing agent can help overcome communication issues and enhance quality control.

Final Verdict: Is China Injection Mold the Best Choice?

Despite its drawbacks, China Injection Mold remains among the most competitive options for injection mold employment because of its low prices, fast production, and improving quality. Nevertheless, the optimal selection depends on business requirements:

- Manufacturers in Germany, Japan, or the USA would be more suitable if ultra-high precision and severe IP protection is required.

- If speed and low cost without compromising quality are necessary, then China Injection Mold is the most suitable choice.

- By vetting suppliers on quality control, cost breakdown, lead time, and several other aspects, businesses can take advantage of China’s Injection Mold industry while minimizing risks.

In Conclusion

The injection mold sector in China is now a contender on a global scale. The country offers cheaper molds of superior quality than what Western manufacturers provide. Certain difficulties, like IP protection and communication issues, persist. However, the lower cost and quicker production make China a useful option for injection mold sourcing. Third-party businesses can achieve improved and cheaper production processes by utilizing Chinese manufacturers through quality assurance measures and robust supplier vetting.